Over the past 15 years the electronic industry has been moving away from lead solder due to environmental, health and safety issues. This has reached a point where a vast majority of ICs are only purchased in lead-free format. To enable this transition, lead-free solder was introduced, but the only catch with lead free solder was that it wasn't as good as leaded solder, for instance it melted at a higher temperature than lead solder.

But certain high reliability industries were made exempt from moving to lead-free, as they were operating in important environments and at the time it was unknown how exactly lead free solder would hold up or perform in harsh conditions. Certain examples are :

Military / Defence - Missiles could be stored long term and then used, due to these extended timelines and the nature of its use it had to be 100% operational, so a risk could not be taken of the solder being lead free as no data was available regarding its long term effects.

Aerospace - Due to the G-force, height, pressure that the aircraft come under, it was as important from the safety standpoint that the aircraft system not to fail mid flight. Lead free solder as with Military / Defence had not proven itself yet to be as robust for harsh environment.

Automative - Due to high heat, vibration and safety issues; critical electronic systems in cars such as braking systems and airbags were also exempt.

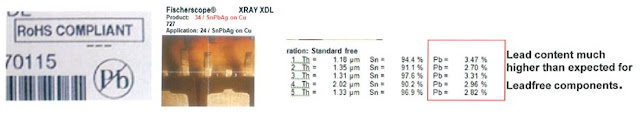

Due to such changes in regulations where most of the other sectors had moved on lead free solder, many IC manufacturers have stopped producing leaded parts, they were producing just lead free parts. One factor that hit High reliability industries was that although high reliability parts cost more than commercial versions, in many cases the small volume consumption of these parts in lead form did not justify setting up a separate line to make a lead version of the component, therefore the high-reliability industries often struggle to find their ICs in the lead format.

Often they would have to buy them in lead free format and convert them to lead format, there is no credible and safe way to do this for BGA other than Retronix - IC Rescue Process, it is the only process that does not use any reflow cycles to achieve alloy conversion and therefore meets the IC manufacturer's specifications. Another issue that keeps the industry restricted at times is that they rely on tried and tested technology especially for missiles, aircraft control systems as they know it works.At time technology used by certain IC manufacturers for making certain components become obsolete and they stop making the parts altoghether, high reliability industries will end up buying a bulk of components with total guess work anticipating future requirements.

So the issues that they could face are :

- They may only buy in lead free format which would have to be converted to Leaded version

- They may not be able to find the ICs at all.

- A component is needed which has been out of production and obsolete.

- Forced to buy large volumes of ICs, this could lead to component packages being broken open, a few are used and the rest become exposed leading to oxidisation and solderability problems.

Each of the problems can be solved and can save high reliability industries from having to spend too much time and effort on the ICs, contact us using this link - http://www.retronix.com/contact-us or email us on info@retronix.com

A few interesting videos on our processes -

.PNG)

.PNG)

.PNG)

.PNG)

.PNG)

.PNG)