A customer sent approx. 5000 parts [BUK139-50DL] to check the authenticity of the components. The customer who had procured these parts believed that the devices were originals and worked perfectly fine. He sent these parts to Retronix for Visual inspection, marking permanency testing, de-cap and a basic electrical test.

First a visual check of the label information was done and it showed on the labels attached on each reel, that the parts were lead free. Moving onto deeper visual checks on the components for the markings and the condition of the terminal told a different story. Retronix used the standard IDEA-STD-1010-B to compare the results.

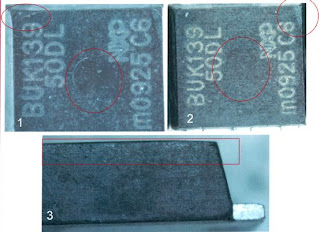

Images 1 & 2 show faint indent markings and corner damage, these signs are evidence of remarking the components. Moreover there was no country of origin on the devices.

Image 3 shows further evidence that parts are remarked/sanded down as the device is uneven.

Parts on the same reel showing different DRAIN tab features, also the top part of the device was in a very poor condition

Further to this, parts from the same reel showed different DRAIN tabs, the condition of the tab was poor, deep scratches and signs of damages to the edge as shown.

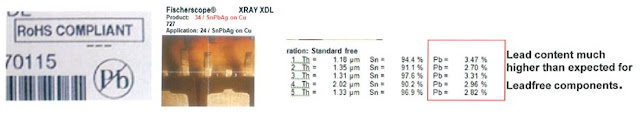

The Retronix testing team then went on to perform an X-ray test of these devices for a more in depth look and as per ERAI-STD-1010-B used for as reference found the following:

The test revealed that different results of die and the drain tab, all the parts on the same reel with the same datecodes should match under the X-Ray. As was mentioned earlier the labels showed all the devices to be lead free, and in order to authenticate this the X-ray test was performed which revealed otherwise.

The de-capsulation test was then done on the devices :

Figure : Images illustrate the topside (1) and the underside (2) of the sample device. Analysis suggests no evidence of attempted re-marking or re-packaging.

The images illustrate the package markings (1) , the entire die surface (2), and the die viewed at high magnification (3) and (4) , with no known good component or information from the datasheet, the die could not be confirmed as genuine. If the information on the datasheet is to be compared to the die, then Retronix believed that there would be more internal circuitry. Moreover no Die markings were found showing part number or the manufacturer.

Further checks revealed that the parts were already reported to the ERAI, where complaints such as parts smoking exploding on the boards were being reported.

Conclusion :

With all the evidence found Retronix believed the parts to be counterfeit components and not suitable for use on PCBs due to the electrical tests that were carried out and also with the information found on the ERAI website.

For more info -

Know more about Retronix | CLICK HERE |

Know more about our IC Testing services | CLICK HERE |

We welcome you to join our LinkedIn group | CLICK HERE |

Contact us : | CLICK HERE | info@retronix.com | sales@retronix.com

YouTube | LinkedIn | Twitter

First a visual check of the label information was done and it showed on the labels attached on each reel, that the parts were lead free. Moving onto deeper visual checks on the components for the markings and the condition of the terminal told a different story. Retronix used the standard IDEA-STD-1010-B to compare the results.

Images 1 & 2 show faint indent markings and corner damage, these signs are evidence of remarking the components. Moreover there was no country of origin on the devices.

Image 3 shows further evidence that parts are remarked/sanded down as the device is uneven.

Parts on the same reel showing different DRAIN tab features, also the top part of the device was in a very poor condition

Further to this, parts from the same reel showed different DRAIN tabs, the condition of the tab was poor, deep scratches and signs of damages to the edge as shown.

The Retronix testing team then went on to perform an X-ray test of these devices for a more in depth look and as per ERAI-STD-1010-B used for as reference found the following:

The test revealed that different results of die and the drain tab, all the parts on the same reel with the same datecodes should match under the X-Ray. As was mentioned earlier the labels showed all the devices to be lead free, and in order to authenticate this the X-ray test was performed which revealed otherwise.

The de-capsulation test was then done on the devices :

Figure : Images illustrate the topside (1) and the underside (2) of the sample device. Analysis suggests no evidence of attempted re-marking or re-packaging.

The images illustrate the package markings (1) , the entire die surface (2), and the die viewed at high magnification (3) and (4) , with no known good component or information from the datasheet, the die could not be confirmed as genuine. If the information on the datasheet is to be compared to the die, then Retronix believed that there would be more internal circuitry. Moreover no Die markings were found showing part number or the manufacturer.

Further checks revealed that the parts were already reported to the ERAI, where complaints such as parts smoking exploding on the boards were being reported.

Conclusion :

With all the evidence found Retronix believed the parts to be counterfeit components and not suitable for use on PCBs due to the electrical tests that were carried out and also with the information found on the ERAI website.

For more info -

Know more about Retronix | CLICK HERE |

Know more about our IC Testing services | CLICK HERE |

We welcome you to join our LinkedIn group | CLICK HERE |

Contact us : | CLICK HERE | info@retronix.com | sales@retronix.com

YouTube | LinkedIn | Twitter