It is a fact that there will always be a certain number of failures when PCB's are manufactured and this is normal due to the nature of manufacturing processes. Typical causes that can cause failures are:

1) Paste issues

2) Raw PCB faults

3) Rogue Solder joints

These faults mentioned above are the first indicator that the components mounted on these PCB's may be good, since they have nothing to do with the faults. Therefore in all probability the ICs may be brand new, unused and in perfect working order.

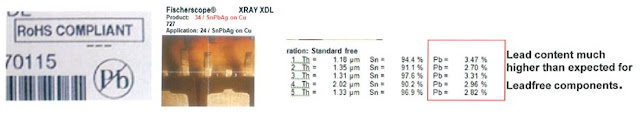

But sometimes company policy states that these failed PCB's be send straight to landfill and recycled, this leaves a lot of potential threats, as certain people with vested interests may get the opportunity to counterfeit these components by using the scrap material from these landfills, also in some cases be sold faulty or completely degraded to unsuspecting customers who buy and implement them in their supply chain leading to huge problems later to deal with.

| Picture used for representation purposes only |

Companies were taking this risk of sending the failed PCBs straight to landfill since there was no safe way of recovering these perfectly good components from PCBs for re-use. However recently there is a process developed that can recover these components for re-use in a very safe manner and without reflow cycles, and this is certainly a much better and economical way to recycle them than to throw the full unit away.

When new components are scarce, as is often the case, their recovery becomes even more important and even more profitable. The risk of dealing in counterfeit components has increased with the 2012 US National Defence Authorization Act. As this global issue becomes more and more of a problem, the ramifications, sentences and fines are becoming increasingly severe. Therefore the best option is to recover this ICs in a safe manner for re-use.

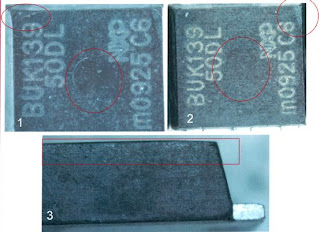

Here is a small demonstration of the process :

By recovering electronic components, up to 50 times the value can be realised from the scrap. The treated scrap, with components removed, could then be sent to any recycler, thereby also eliminating counterfeiting and the re-circulation of faulty and degraded parts.

E - info@retronix.com, sales@retronix.com

Contact us - http://www.retronix.com/contact-us

.PNG)

.PNG)

.PNG)

.PNG)

.PNG)

.PNG)

.PNG)